Last Revised: July 08, 2022

Revision 7/2022

The requirements in Penn's Chemical Hygiene Plan SOP: Corrosives and SOP: Strong Oxidizers apply to all work methyl methacrylate (MMA) (CAS#80-62-6). The Fact Sheet below gives hazard information and precautions for working with this chemical; however, this information is provided as a supplement to the SOPs, which must first be read and understood by anyone planning to work with this chemical.

Methyl methacrylate (MMA) embedding is a common procedure in light microscopy specimen preparation and was the first resin that was widely used for electron microscopy sample preparation. Advantages of MMA embedding include its low viscosity and high hardness of the resulting polymer. These properties enable thin cuts of sections and processing of harder samples. In fact, it is the primary method for processing undecalcified bone. This Fact Sheet provides guidance on the general hazards and controls of this process.

Hazard Description

The embedding process involves the use of the hazardous chemicals MMA, xylene, and benzoyl peroxide. MMA and xylene are both flammable; MMA is also an irritant. Benzoyl peroxide is a strong oxidizer that can cause irritation to the eyes, skin, and mucous membranes. It can also cause sensitizing dermatitis. See SOP: Strong Oxidizers for more information.

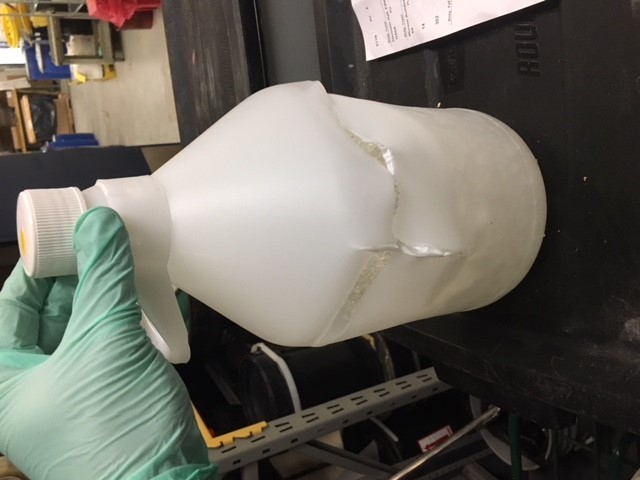

The waste stream that results from using an organic peroxide (benzoyl peroxide) in conjunction with a polymer (MMA) and flammable liquid (xylene) can create hazardous conditions. EHRS has responded to several incidents of container ruptures on campus involving this waste stream. The photo below is an example of one such rupture. Special care must be taken if you generate waste containing these chemicals.

Embedding Process

The following is a list of safety guidelines for those researchers conducting MMA embedding in their lab.

This Fact Sheet does not provide procedural instructions for the embedding process, only safety guidelines and waste disposal procedures. Refer to protocols in the literature or established by your laboratory for the embedding process.

This Fact Sheet contains some important reminders, but it does not replace the need for live demonstration, hands-on training, and supervised practice.

Approvals and Training

If you or your lab has not worked with this hazard before and you are considering a procedure that requires you to do so, we recommend contacting EHRS for guidance.

All work that involves the MMA embedding process requires the approval of the P.I. The P.I. must ensure that the person or team who will be working with the equipment understands the hazards and has received adequate training and supervision for the procedure. Hands-on, in-lab training and supervision is required for inexperienced researchers; in-lab training must be documented.

Approvals, limits and training pertaining to the use of corrosive chemicals and gas-producing waste also applies to any labs using MMA embedding procedures. For more information, refer to SOP: Corrosives and Fact Sheet: Gas-Producing Waste.

PPE Requirements

Wear disposable nitrile gloves during all steps. Nitrile gloves only provide short term protection to small splashes. If the gloves get contaminated with MMA, take them off as soon as possible and wash your hands. Dispose of the contaminated gloves and put on a new pair. If you expect more than incidental exposure to MMA, you must wear supported polyvinyl alcohol (PVA) gloves. Wear safety glasses or chemical-splash goggles when working with MMA. For more information, see Lab Coat, Gloves, and Safety Eyewear Policy.

Handling of MMA & Waste Disposal

Improperly managed MMA waste can result in ruptured waste containers, which could cause injury and property damage.

Before you begin work with any of these materials, request an HDPE (plastic) waste bottle and vented cap from EHRS using the Chemical Waste Pickup Form. These wastes must never be stored in glass containers.

Only one person at a time should be conducting embedding procedures. The second person can only start the process once the embedding is completed. This helps to limit the amount of MMA waste generated in the lab.

Conduct the entirety of the embedding activities in a fume hood. Ensure the fume hood is working properly before proceeding. Always work with small batches not to exceed 1/3 capacity of a 1-L or 1-gal HDPE bottle.

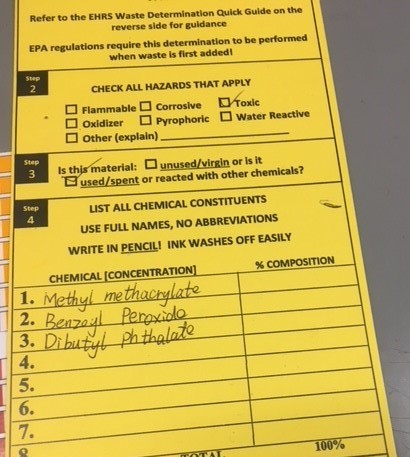

Once the casting resin is mixed, dispose of any excess into a 1-L or 1-gal HDPE bottle contained inside a yellow 5-gallon reactive bucket with the vented cap left off for 24 hours. Label the bottle using a yellow chemical waste label, which lists all components of the waste stream using full chemical names. Date the waste tag when the container is started. Communicate this status on the waste label or on the bottle itself.

Following this initial 24 hours, the vented cap can be loosely affixed to the waste bottle and must continue to be stored inside the fume hood in the yellow reactive bucket. Communicate the status of the loose cap on the waste label or on the bottle itself.

After 48 hours, and if no further batches of casting resin are to be made in excess of 1/3 capacity of the 1-L or 1-gal HDPE bottle, request waste disposal using the Chemical Waste Pickup Form.

Bulging or ruptured containers and spills must be reported to EHRS immediately: 215-898-4453.

Methyl methacrylate must be disposed of within one year from the date of opening/within the expiration date which is usually one year.

For more information, see Fact Sheet: Gas-Producing Waste.