Last Revised: April 10, 2024

Revision 6/1/2021

Hazard Assessment

Conducting experiments at elevated temperatures increases the risk of fire, explosion, over-pressurization, and chemical exposure. Assess all hazards prior to beginning experiments at elevated temperature. Consider the chemicals’ boiling points, flashpoints, and potential for thermal decomposition temperature, as these will determine the temperature to which you can safely heat the materials. Evaluate not just the starting materials, but also the products and byproducts of side reactions for their thermal stability. Also, take into account the reactivity between materials and determine if there is a potential for runaway reaction, production of gas, or explosion. If you need assistance assessing the properties of your materials or reactivity hazards, consult your supervisor, contact EHRS, or see the Chemistry Department Librarian for resources. There are certain chemicals that should not be heated, for example pyrophoric compounds, strong oxidizers and peroxides. Never heat any mixture or solution that evolves vapors in a closed system unless you have taken into account the pressure that will be produced as a result. When scaling up a reaction, reevaluate the hazards, especially if it is more than triple the original scale.

For specific guidance on agarose heating safety, see Fact Sheet: Agarose Heating Safety.

Typical Set-Up

Hot plates, heating mantles, and heating blocks are common methods of elevating reaction temperature. Never use an open flame (such as a Bunsen burner) to heat a reaction. Assemble your equipment in a way that allows you to quickly remove the heat source without disrupting the mixture being heated. You can accomplish this by using lab jacks and clamps.

Use a stir mechanism in all reactions to prevent uneven heating. When selecting a stir method, take into account the viscosity of the mixture and the importance of even mixing for the reaction. Select a magnetic stir bar of adequate size or consider whether overhead-mechanical mixing is required.

Reactions heated to near or above the solvents boiling point require additional controls to prevent the vaporization of solvent and increase in pressure. Use a condensing apparatus and continuously vent the system through a bubbler. When an inert atmosphere is required, use a schlenk line with an exit bubbler rather than a balloon for proper venting.

For any reaction that might evolve gas (and all distillations), only hose/adapter attachments should be used. Avoid use of any constrictions, such as a needle. Needles, even wide gauge, can easily clog leading to such events. Even stopcock connectors need to be carefully considered.

Use non-combustible insulating materials to insulate distillation pots.

Personal Protective Equipment (PPE)

Wear standard personal protective equipment (gloves, lab coat and safety glasses) at all times. Heat-resistant gloves are recommended for handling hot glassware or baths.

Engineering Controls

The type of heating device used and how it is used affects the safety of the experiment. See Hot Plate Malfunctions and Misuse Safety Alert for more information about selecting the right equipment and safe practices for using hot plates and heating mantels.

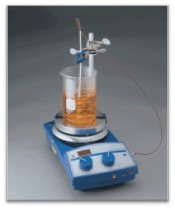

Always use the following engineering controls to reduce risk; see photo below.

- Use thermocouple/thermostat controlled heat when available (such as the apparatus shown below).

- Clamp thermocouple probe securely in heating bath medium.

- Directly monitor the temperature of the mixture via a multi-neck flask with thermometer adapter whenever temperature stability is critical.

- Secure condenser tubing with wire to avoid leaks/floods – avoid mixing water and hot oil, this will lead to splattering of the hot oil.

- Use a lab jack for quick removal of the heating bath from the reaction flask.

- Consider whether the hazards warrant the use of a blast shield.

Administrative Controls

Always use the following work practices to reduce risk.

- Remove all unneeded flammable and combustible materials from the fume hood prior to heating a reaction.

- Allow reaction to cool completely to room temperature before handling.

- Use the timer on the hotplate (if equipped) to control the length of time heat is applied, or use an audible timer as a reminder to check your reaction and/or adjust the heat when necessary.

- Allow reaction to reach target temperature and equilibrate before you walk away from the hood.

- Label stir and heat knobs clearly.

- Do not leave heated reactions unattended

If the hot plate must be used while unattended, make a plan for reducing the risks

- Post an “Unattended Operation” sign describing the reaction or materials that are being heated. Include the date and emergency contact information for the person responsible for the work. (Download a template below)

- Double check that all flammable and combustible materials have been removed from the hood.

- Set the adjustable over-temperature control (if equipped) to at least 15 degrees (C) under the safe temperature limit for the operation. (This is control is usually set using a screwdriver on the side or back of the device as pictured. See operator manual for instructions on setting this maximum temperature. Factory settings may be higher than desired.)

- Securely clamp condenser hoses and temperature probes.

- Do not leave the apparatus unattended until the target temperature has been reached and is sustained.

Different Heating Methods

Oil baths are the most commonly employed method for heating a reaction as they provide the best heat transfer from the heat source to the reaction mixture. However, the use of oil baths is not without risk. Use thermocoupled or thermostat-controlled heat sources whenever possible. Immersion-heating coils (shown below) with exposed electrical conductors are NOT permitted as a heat source.

Ensure that liquid heating baths sit level on the heating apparatus, and monitor temperature at all times. Regardless of the media you are using, do not fill the bath containment vessel more than half way.

Discard bath media that has become discolored, such as the material shown to the left. The black color indicates a breakdown of the oil and contamination from spills, which can change the media’s properties. Clean up spills of oil immediately. Hexanes, and other non-polar solvents are most effective at cleaning up oil spills. Collect and label waste oil separately from other waste streams. Indicate any known chemical contamination on the waste label.

Depending on the reaction conditions, different bath materials will be required. Ensure that the bath medium is capable of safely heating to the desired temperature. The table below lists some of the most used media and their properties. The media should never be heated over its flash point.

|

Bath Material |

Flash Point (oC) |

Useful Range (oC) |

|

Water |

NA |

0-70 |

|

Mineral Oil |

113 |

25-100 |

|

Silicone Oil |

300 |

25-230 |

|

Eutectic Salt Mixtures (51.3% KNO3; 48.7% NaNO3 or 40% NaNO2; 7% NaNO3; 53% KNO3) |

NA |

142-500 |

|

Sand |

NA |

25-500+ |

Most oil baths are good for heating reactions <200 oC as they provide a more even distribution of heat and are easier to regulate. For reactions requiring higher temperatures, heating mantles and sand or salt baths must be used. Heating mantle apparatuses are controlled using a variable voltage regulator (Variac), and therefore the reaction temperature must be monitored directly. Never rely solely on the relative voltage on the dial to determine what temperature to which the heating mantle will rise. Always adjust the voltage incrementally until the desired temperature is reached and stabilizes.

General Hot Plate/Heating Mantel Procedures

- DO NOT store flammables or combustible materials on or near the heating apparatus.

- Unplug heating equipment when not in use, or use an appliance timer to ensure that the heat source is disconnected from power when the lab is unoccupied. [See: Safety Alert: Hot Plate Malfunctions]

- Use stir-only plates when stirring in containers that are not heat-resistant or mixing materials that should never be exposed to heat, such as those with the potential to ignite, explode, or release gas when heated.

- Never use hot plates in the cold room. The cold and condensation can damage the equipment.

- Double check that the thermocouple is securely in bath to prevent uncontrolled heating.

- Do NOT use heating equipment with damaged cords or plugs or equipment that is not functioning as designed.

Emergencies

Emergency Contacts

General emergency response information can be found at Emergency Info

Fire

NEVER try to put out an oil bath fire with water. Always keep sand in an easily accessible place to quench fire.