Last Revised: April 12, 2024

Revised 7/2022

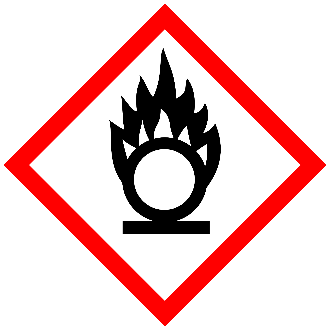

Hazard Description

Oxidizing chemicals are materials that spontaneously evolve oxygen at room temperature or with slight heating or promote combustion. This class of chemicals includes peroxides, chlorates, perchlorates, nitrates, and permanganates. Strong oxidizers are capable of forming explosive mixtures when mixed with combustible, organic or easily oxidized materials. Examples of strong oxidizers are listed at the end of this SOP in the section called "List of Strong Oxidizers."

Approvals

If you or your lab has not worked with this hazard before and you are considering a procedure that requires you to do so, we recommend contacting EHRS for guidance.

Contact EHRS before purchasing concentrations of perchloric acid greater than 40%.

All work that involves the handling or transfer of strong oxidizer chemicals requires the approval of the P.I. The P.I. must ensure that the person or team who will be working with the strong oxidizer chemicals understands the hazards and has received adequate training and supervision for the procedure.

For any task that requires safety controls beyond those specified in this SOP, a task-specific Hazard Control Plan (HCP) must be written. The HCP must be sent to EHRS for review. EHRS will upload the HCP to the “documents” section of the lab’s BioRAFT page.

Training Requirements

No researcher may work independently with the hazardous material described in this SOP until the Principal Investigator (or their designee) has ensured that the researcher:

- Has completed all required EHRS laboratory safety training programs

- Understands the hazards of the materials and risks of the processes involved

- Has read and understands the contents of this SOP

- Demonstrates the ability to execute their work according to the requirements in this SOP

Facility Requirements

General Ventilation

Strong oxidizer chemicals may not be handled or stored in a room or facility with recirculating exhaust.

Chemical Fume Hood

All work with strong oxidizer chemicals in open or closed systems must be done in a designated area of a laboratory inside of a properly functioning chemical fume hood.

Emergency Irrigation

Emergency irrigation (safety shower, eyewash) must be accessible within a 10-second travel distance of the area where the work is performed.

Signage and Labeling

A legible manufacturer’s label including hazard information must be present on all commercial containers of strong oxidizer chemicals.

If strong oxidizer chemicals are transferred to another container for storage or to make stock solutions for later use, special labeling requirements apply. See the “Researcher-Created Labels” section in Section IV: Chemical Container Labeling in this CHP for a complete list of requirements.

Storage and Transport

Proper storage and transport of strong oxidizer chemicals must be determined by assessing all of the hazards and physical properties of the chemical.

See Section VI: Chemical Storage and Transportation in this CHP for a complete list of requirements.

Specially designed corrosion-resistant cabinets should be used for the storage of corrosive materials. For new lab construction, renovations, and whenever possible in existing labs, the specifications for corrosive cabinets found in the Laboratory Design & Equipment section of the EHRS website should be followed.

If no corrosion-resistant cabinet is available, store corrosives on plastic trays.

Do not store corrosive liquids above eye level.

The SOP: Corrosives contains more detailed information about expiration intervals and storage issues for concentrated strong acids.

Hazard Controls

Engineering Controls

Chemical Fume Hood

Work with strong oxidizer chemicals in open or closed systems in a designated area of a laboratory inside of a properly functioning chemical fume hood. Contact EHRS if you are unsure of the ventilation requirements for your procedure.

When heated, perchloric acid may only be used in a fume hood equipped with a wash down feature. Contact the Office of Environmental Health and Radiation Safety for fume hood requirements.

The fume hood is designed to capture chemical vapor and the hood sash acts as a shield in case of chemical splash. The sash must be kept closed as much as feasible.

Vacuum Protection

Mechanical vacuum pumps must be protected using cold traps and, where appropriate, must include a filter to prevent particulate release. The pump exhaust must be vented into an approved exhaust duct or chemical fume hood.

Work Practices

A list of recommended work practices for hazardous chemical handling is included in Section V: Chemical Handling in this CHP. Of particular relevance to strong oxidizer chemical use:

Considerations for purchase

- Do not use strong oxidizer chemicals if less-hazardous alternatives are possible.

- Purchase, dispense, and use the smallest quantity of strong oxidizer chemicals possible.

- Purchase the lowest concentration of strong oxidizer chemicals that will meet your research needs.

Considerations for work space

- Do not store corrosive chemicals in chemical fume hoods or allow containers of strong oxidizer chemicals to come in contact with heating mantles, hot plates, or torches.

- Strong oxidizers are incompatible with organic materials and may ignite on contact with cellulose-based materials like paper and cardboard. Keep all organic reagents, solvents, paper, and wood away from the area where strong oxidizers will be stored and handled.

Considerations for handling

- Do not handle strong oxidizer chemicals when working alone.

- Immediately close all containers of strong oxidizer chemicals after use.

- Due to the risk of splashes and equipment failures, do not use a syringe and needle to perform transfers of strong oxidizer chemicals in volumes of greater than 5 mL.

- Perform liquid transfers slowly using a funnel to minimize slash, splatter, and spills.

- Do not pour water into acid. Slowly add acid to water while carefully stirring. Some strong oxidizer chemicals will generate heat and/or release gas on contact with water. Understand the potential for reaction with water before diluting a chemical. The water may need to be cooled with continuous stirring while acid is added.

- Reactions involving strong oxidizer chemicals are often very exothermic. Use heat-resistant labware and allow extra volume in your vessel to account for expansion and/or foaming. It may be necessary to pre-cool solutions and cool while mixing or reacting.

Additional work practices for reducing the risks of any lab procedure involving strong oxidizer chemicals must be described in a written Hazard Control Plan.

Personal Protective Equipment

Consider the potential routes of exposure and health consequences when selecting personal protective equipment (PPE) for tasks involving strong oxidizer chemicals.

The minimum PPE requirements for all chemical handling tasks, and information about specialty PPE can be found in the "Personal Protective Equipment" section of Section V: Chemical Handling in this CHP.

In addition to the minimum lab apparel and PPE requirements, other protective equipment may be necessary to reduce risks. When additional equipment (such as tight-fitting chemical splash goggles, chemical-resistant gloves, or disposable lab coats) are required, a Hazard Control Plan must be written to document the risk assessment and controls.

An example of a task that would require additional eye/face protection:

- Transfers of corrosive liquids outside of the fume hood.

- Due to the increased risk of splash to the face and eyes when there is no hood sash to shield the worker, tight-fitting chemical-splash goggles and a face shield are required.

Examples of a tasks that require specialty gloves:

- When prolonged contact or immersion of hands in corrosive liquid is anticipated

- When large volumes of corrosive liquids are being transferred

- Handling particularly toxic corrosive chemicals

Contact EHRS for assistance with risk assessments, glove compatibility, and other PPE selection.

Waste and Decontamination

Wash hands thoroughly with soap and water after handling any chemical and whenever you leave the lab.

Use good housekeeping practices to avoid contamination of surfaces, garments, personal belongings, and self.

Decontaminate all surfaces that have come in contact with strong oxidizer chemicals and clean-up small spills promptly. See the chemical Safety Data Sheet or contact EHRS for assistance with determining an appropriate decontamination method.

Spill control materials for oxidizers are designed to be inert and will not react with the reagent. Never use paper towels or other inappropriate materials which are combustible. The waste materials generated during spill cleanup may pose a flammability risk and should not remain in the laboratory overnight unless it is stored in an appropriate container.

See “Spills” below for instruction on what to do in the event of a large or hazardous spill of a strong oxidizer chemical.

Strong oxidizer chemicals are hazardous wastes.

Waste streams that include a mixture of corrosive liquids and peroxides (such as Piranha etch, Chromerge, and Nochromex) produce gas and require special waste procedures. See the CHP Fact Sheet: Gas-Producing Waste for more information.

For complete hazardous waste guidelines, see the waste section of the EHRS website: Laboratory Chemical Waste Management Guidelines

Emergencies

Emergency Contacts

General emergency response information can be found at Emergency Info

Spills

General procedures for chemicals spill response can be found in Section X: Chemical Spills in this CHP.

Do not hesitate to call EHRS for assistance with spill cleanup for corrosive materials.

24 hours: 215-898-4453

Contact Penn Police (511) only if the spill involves a fire, imminent risk of fire, an injury requiring an ambulance, or if there is a hazard that may affect others in the building.

List of Strong Oxidizers

This list gives examples of strong oxidizers chemicals found in research laboratories. It is not a comprehensive list. Consult the Safety Data Sheet to determine the hazards of each chemical you use.

|

Ammonium perchlorate |

Ammonium permanganate |

Source: CRC Handbook of Laboratory Safety, 3rd edition.

Related SOPs and Fact Sheets

References

This SOP was based on the previous version of “EHRS SOP for Corrosive Chemicals” and the following additional resources:

(none provided)