Last Revised: June 26, 2025

Revision 6/2025

This Fact Sheet provides an introduction to equipment used for storing, transporting, and delivering liquid cryogens and gases from liquid cryogens. For complete guidance on the safe storage and handling of cryogenic materials, see the following SOP in the Chemical Hygiene Plan: SOP: Cryogens and Dry Ice

Dewar Definition

A dewar is an insulated container used for storing cryogens. Most dewars are double-walled and vacuum-insulated; some also use an insulated packing material in the vacuum jacket. Dewars used for temporary storage of cryogens may be constructed of foam insulation. See below for information about the different types of cryogen dewars found in research labs and descriptions of how they are used.

Atmospheric-Pressure Storage and Transport Dewars

Dewars are used for sample storage, transport of cryogens from source -to-point of use, and temporary benchtop storage of cryogens for immersion of samples and flasks.

-to-point of use, and temporary benchtop storage of cryogens for immersion of samples and flasks.

Under no circumstances should cryogens be stored or transported in a container that is not designed specifically for cryogenic storage or transport. Insulated beverage containers, glass labware, and other non-approved vessel are not designed to vent properly or to withstand cryogenic temperatures and must not be used.

Pressurized Cryogen Dewars

Cryogenic liquids such as liquid nitrogen and argon are dispen sed from pressurized dewars that vary in capacity between 60 and 265 liters. These large, pressurized dewars can be used for dispensing liquid cryogens, but can also be used when high volumes of gas are required for lab processes.

sed from pressurized dewars that vary in capacity between 60 and 265 liters. These large, pressurized dewars can be used for dispensing liquid cryogens, but can also be used when high volumes of gas are required for lab processes.

The equipment described below is a common type of liquid nitrogen dewar used on Penn’s campus. For information about pressurized dewars for other cryogenic liquids, contact EHRS.

Liquid nitrogen service is provided to the labs in one of the two ways described below.

Liquid-nitrogen fill station on campus

- The pressurized dewar is owned by the laboratory or department, and is refilled by trained staff on campus.

- The dewars owned by Penn labs or departments must be sent to a gas vendor for inspection and maintenance whenever the equipment shows signs of malfunction or damage. Contact EHRS for more information about dewar inspections and repair.

Gas-supply companies

- Full dewars are delivered to the building or laboratory by the gas supplier.

- The laboratory does not own the dewar. The contract is for the liquid nitrogen product.

- Dewars from gas suppliers may not be refilled at Penn liquid nitrogen fill stations.

Pressure settings

Industry-standard pressure settings for liquid nitrogen dewars classify them as Low Pressure, Medium Pressure, or High Pressure depending on the operating pressure of the dewar. The pressure rating for the safety relief vent are generally set by the manufacturer as follows:

| Low Pressure | 22 psig |

| Medium Pressure | 230 psig |

| High Pressure | 350 psig |

Low-pressure dewars are used for liquid withdrawal. Medium and high-pressure dewars are used for gas withdrawal. Dispensing liquid from a medium or high-pressure dewar is not recommended as it may cause splashing and/or transfer-line whip and increases the risk of exposure and cryogenic burns. Only low-pressure dewars may be used for dispensing liquid nitrogen.

Low-Pressure Cryogen Dewars

Low-pressure dewars are used for supplying cryogenic liquid only. Pressure-relief valve setting: 22 psi

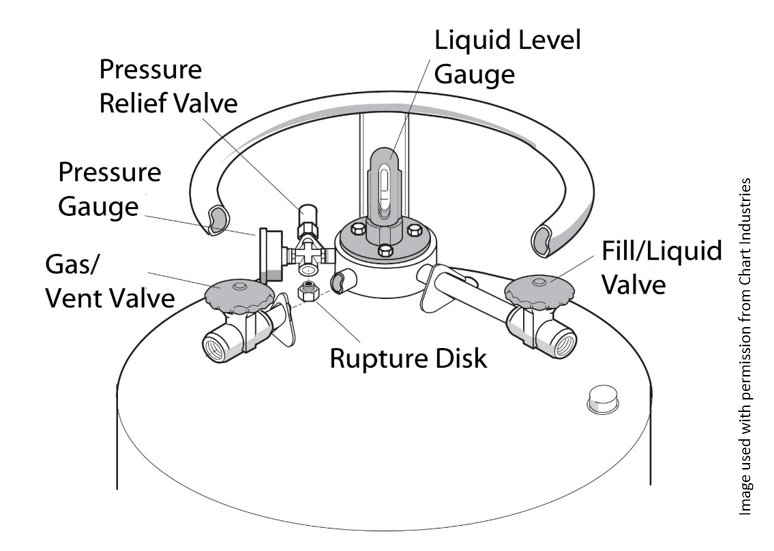

In a low-pressure liquid nitrogen dewar, the pressure inside the vessel is maintained through the normal heat-leak of the cylinder. As the liquid warms, it evaporates and expands to almost 700 times its liquid volume, which increases the pressure inside the vessel. When the pressure reaches 22 psi, it will automatically vent through the pressure relief valve. If the relief valve fails, the emergency rupture disk will vent the excess pressure so that the cylinder does not fail.

Medium and High-Pressure Cryogen Dewars

Medium and high-pressure dewars are used for supplying gas. Pressure-relief valve setting: 230 psi and 350 psi

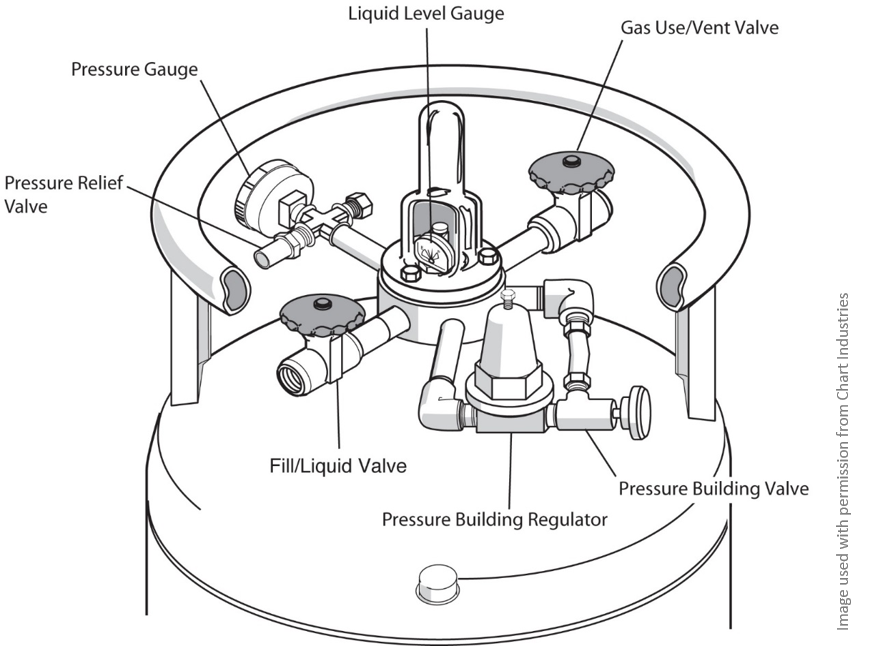

Medium and high-pressure dewars are used for delivery of gas. The two types of dewars function very similarly but differ in the amount of liquid cryogen they can contain. The gas delivery pressure is not the same as the vessel’s operating pressure. Delivery pressure must be controlled using a separate regulator connected to the gas-use fitting.

Medium and high-pressure tanks increase internal pressure by means of a vaporizer coil in vacuum insulated outer jacket of the dewar. When the pressure build valve is opened, liquid enters the coil and is warmed, evaporating and expanding to gas.

When the internal pressure of the cylinder reaches the pressure-relief set point (230 psi for medium-pressure, 350 psi for high-pressure), the relief valve will open and vent gas to reduce the pressure. If the relief valve fails, the emergency rupture disk will vent the excess pressure so that the cylinder does not fail.

Consult the equipment manufacturer’s operating manual for the recommended pressure settings and flow rates for your equipment. If flow rates are too high, the gas from the dewar will be very cold and may result in excessive ice accumulation on the dewar’s controls and valves and damage to the attached equipment.