Last Revised: January 09, 2025

Revision 04/2021

--

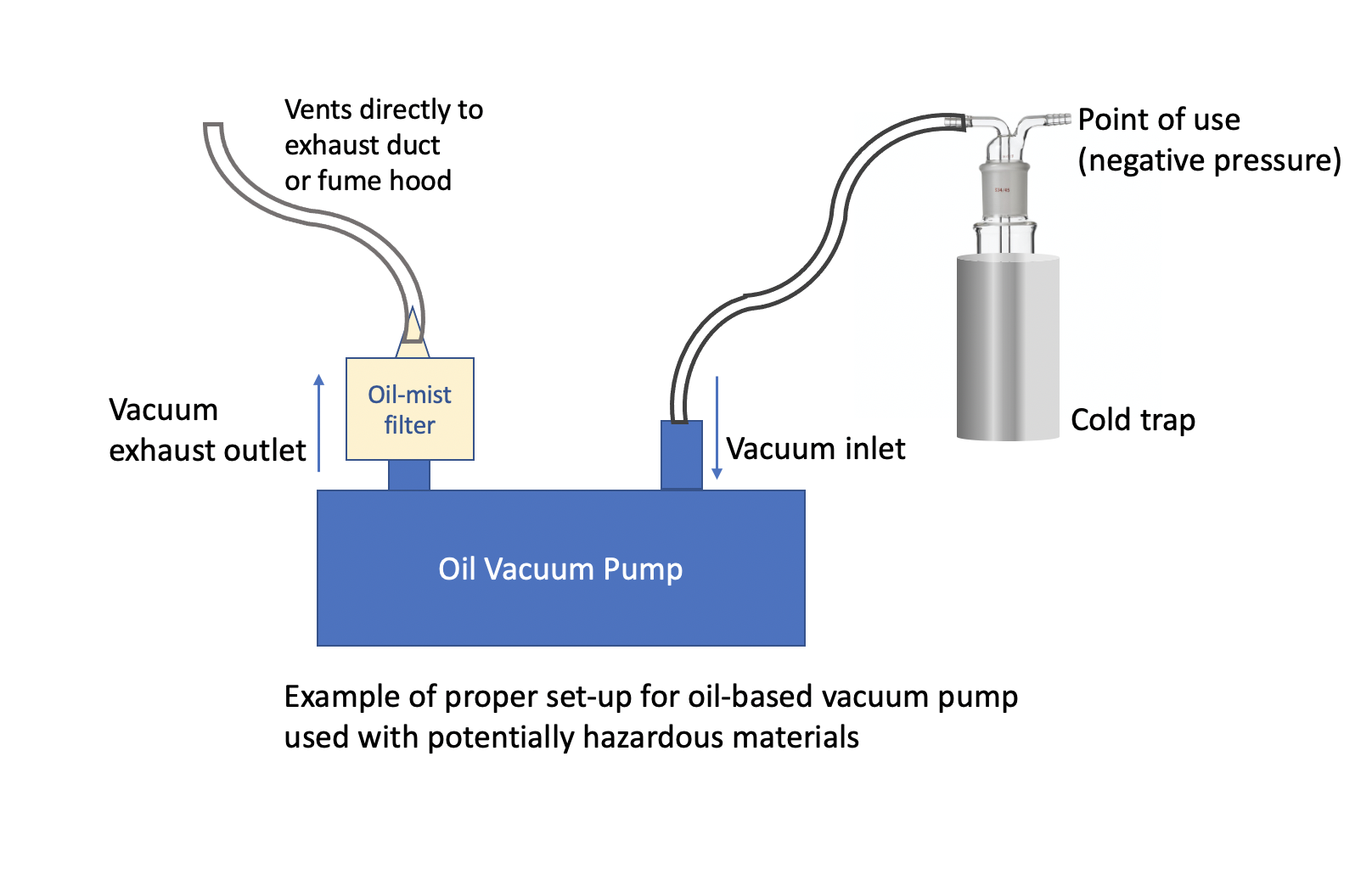

Vacuum pumps are used in a wide variety of experimental set ups. If vacuum pumps are not properly installed, trapped and exhausted they may expose you to hazardous chemicals and vapors.

Operation Checklist

- Belt guards must be in place for all belt-driven pumps.

- Service cords and plugs must be free of defects.

- Plug the pump directly into an outlet. Do not connect to an extension cord or power strip. See the Electrical Safety Fact Sheet for more information.

- Locate in a vacuum pump cabinet (if one is available) or other ventilated cabinet such as a fume hood.

- Operate pumps away from containers of flammable chemicals and flammable chemical wastes.

- For all systems involving potentially hazardous materials, vacuum exhaust for must be vented to a laboratory exhaust duct or fume hood. The exhaust ports of pumps stored in vacuum pump cabinets must be connected directly to the vent port inside the cabinet. The pump may not vent into the cabinet interior. Contact EHRS if you are unsure how to properly vent your vacuum pump.

- Ensure that exhaust tubing is not kinked.

- Place the pump on a tray so that spilled oil is contained.

- Shield any glassware under vacuum.

- Pump oil may be contaminated and should be disposed as chemical waste.

- Pump oil must be compatible (i.e. do not use hydrocarbon pump oil with oxidizing gases or vapors) with the vapors that will pass through the pump.

- Monitor the level of pump oil to ensure it is not low or overfilled.

- Use a cold trap to prevent the degradation and contamination of pump oil.

- Keep combustibles such as paper and cardboard away from pumps. Diffusion pumps contain oil at very high temperatures.

- Connect the pump inlet and outlet properly. Pump connections can look the same. Reversing the flow direction can pressurize apparatus leading to rupture, failure of vessel, or oil contamination.

- If the vacuum pump cabinet has a cooling fan on the rear wall, ensure that the grate on the fan is free of dust and debris. This fan helps remove excess heat from the pump cabinet.

Cold Trap

A cold trap must be placed between the pump and the experiment to minimize the amount of volatile chemicals from reaching the pump oil. Pump oil will break down if exposed to high concentrations of solvents from the vacuum line. This can result in pump damage. EHRS recommends using a second cold trap between the pump and the experiment for added protection. See Safety Alert: Vacuum Pump Explosion in Chemistry Building for more information.

The trap must be adequately sized and cold enough to condense vapors in the experiment. Extreme care must be exercised to prevent the introduction of room air into a trap containing liquid nitrogen. Liquid Nitrogen condenses oxygen and this may cause an explosion. See SOP: Cryogens and Dry Ice for more information about preventing the formation of liquid oxygen and what steps to take if you observe that oxygen has condensed.

Maintain trap during the experiment. Check frequently for blockage. Empty the condenser trap immediately after evaporation is complete to eliminate the possibility that solvent will evaporate as the condenser warms to room temperature.

Use with Hazardous Chemicals

Vacuum pumps which are used to evacuate systems containing toxic, corrosive or volatile substances must be vented into the building’s exhaust system. Failure to properly vent the pump can result in contamination of the lab with hazardous chemical vapors. See Safety Alert: Vacuum Pump Explosion in Chemistry Building for more information. The Safety Alert also provides guidance for selecting the appropriate pump for your research needs.

Use an oil mist separator (purchased from the pump vendor) to prevent oil loss.

Connect the exhaust line to the exhaust port in the vacuum cabinet (if one is present) using a thimble connection or run the hose into the fume hood.

Note that some oil mist separators may not fit into your vacuum pump cabinet. Measure before you order.

Some vacuum pumps cannot accommodate the type of oil-mist separator that has an outlet for exhaust tubing. In this case, safe venting of the pump exhaust to the hood or to an exhaust duct is the more important hazard control.

To accomplish this, tubing must be connected directly to the exhaust outlet on the pump and routed into the hood or exhaust duct port. Trim the tubing to a length that reaches the port without sharp bends/kinks that could obstruct the flow of the pump exhaust.

To help reduce oil loss, ensure that the tubing is sized properly and secured in such a way that oil will drain back into the pump instead of collecting in the tubing.

Pumps for rotary evaporators must be located in a fume hood, vent to dedicated lab exhaust, or be equipped with adequate condensers and traps to prevent emission of solvent vapors into the lab.

Pump Maintenance

- Vacuum pumps must be serviced by an authorized vendor on the schedule recommended by the pump manufacturer.

- Keep detailed records of all pump maintenance including routine maintenance and vendor-provided services.

- Routine maintenance such as pump-oil changes may be performed by lab workers. Follow all manufacturer recommendations for oil changes and routine maintenance.

- Never service a pump that is connected to power. Allow the pump to cool completely before venting or servicing, and disconnect it from power completely. Pumps may start automatically if connected to a power source. If the pump cannot be unplugged directly, contact EHRS for information about lock-out/tag-out before attempting to service the equipment.